Collaborative projects

New materilals

Graphil (Graphene Enhanced Filters for Water Purification)

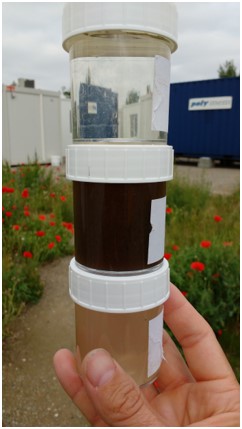

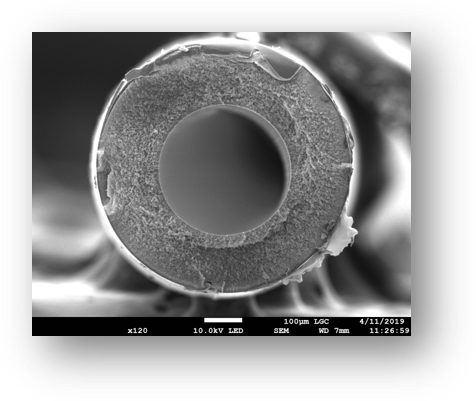

Hollow Fiber Membrane: Secure Residential water quality by removing bacteria, virus and micropollutants in a single filtration step.

Polymem and its partners are developing new tap water cartridges incorporating graphene oxide in hollow fiber membranes.

The end goal of Graphil is the production and commercialization of safe, innovative filters for household water treatment and for portable water purification devices exploiting graphene and related materials. Graphil products will target an urgent market and societal need: the removal of emerging concern contaminants (ECs), molecules with suspect or certified effects on public health including pesticides, pharmaceuticals, per fluorinated compounds, disinfection-by-products, heavy metals and new pathogens increasingly present in water sources, because resistant to conventional purification technologies. GRM are effective in removing the new ECs and are the most promising technology enabling this application today.

Funding :

Partners :

How to operate membrane filtration unit without any needs of cleaning.

Design of a new membrane material for the filtration and reuse of urban wastewater: A response to membrane clogging in tertiary treatment.

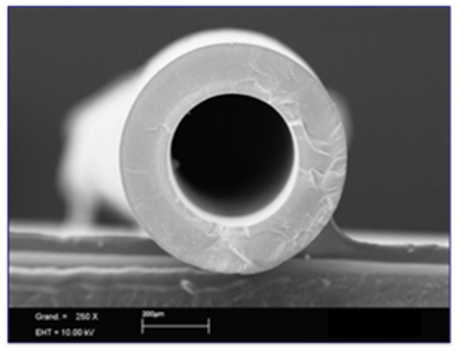

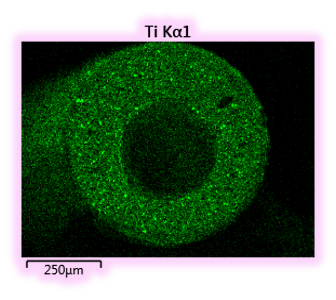

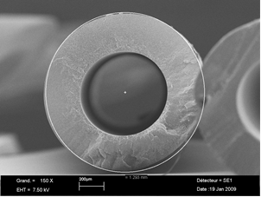

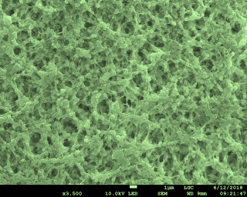

Incorporation of TiO2 (colored in green in SEM picture) in PVDF hollow fiber fabrication.

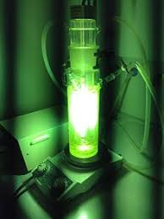

Coupling with UV light for photo-catalytic oxidation of the cake layer.

Funding :

Partners :

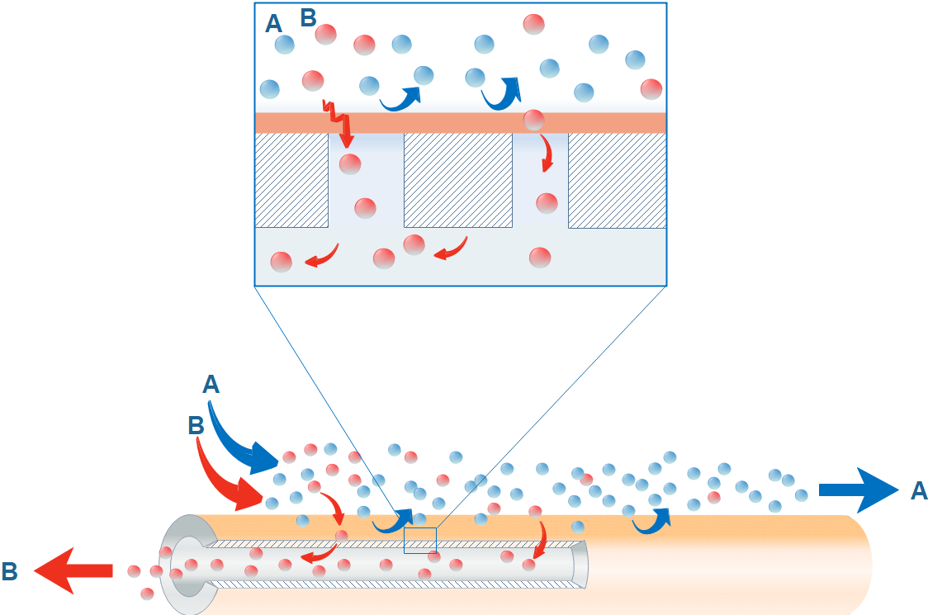

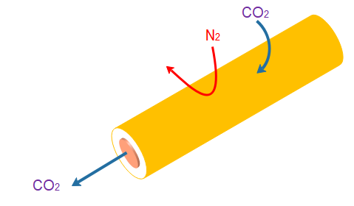

Ideal for CO2/N2; CO2/CH4; CO2/H2; N2/O2; H2Ov separation

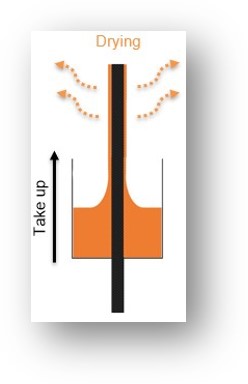

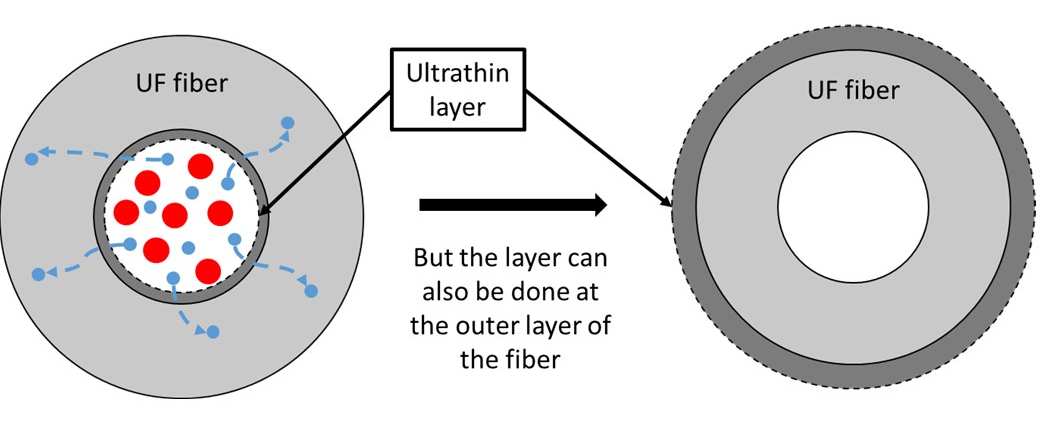

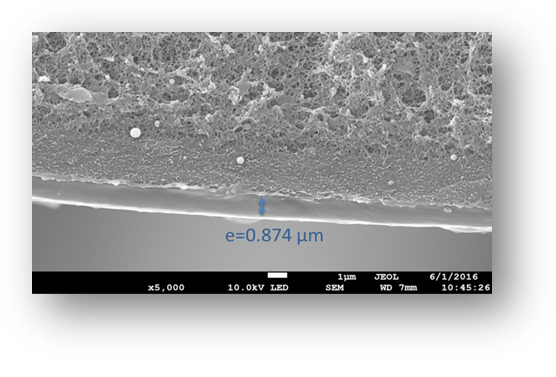

Porous fiber is coated with an ultra-thin dense skin (between 0.5 and 1.0 µm) of permselective polymers. In line coating, from spool to spool, at high take-up speed rate.

Diagram :

Gas B is more permeable than A through the dense skin

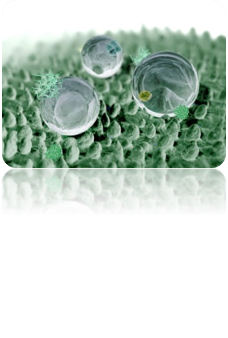

For ultrapurewater degassing and membrane contactors. The LOTUS Leaf effect.

Polymem and its partners succeeded in the fabrication of a PVDF membrane with a superhydrophobic outer surface like the LOTUS Leaf. Contact angles of at least 125° are obtained using an innovative way of membrane fabrication by phase inversion.

Partners :

M2LAB

The Swiss Knife for these membrane separation processes : Reverse Osmosis, Nanofiltration, Forward Osmosis, Gas Separation.

The membrane research group (CREG) from the Chemical Engineering Department of the University of Zaragoza (Spain) and Polymem have given rise to a new project. A phD student from the University has spent several months in Polymem to explore strategies to scale up the inner surface modification of UF Hollow fibers to make them suitable for nanofiltration and reverse osmosis.

Logos :

CO2 Capture and valorization

CO2 CAPTURE FOR AIR QUALITY IMPROVEMENT IN AIRPLANES CABINS

AIRCLEAN

Polymem is contributing to the development and manufacturing of a CO2 membrane extractor with:

- development of membranes by coating

- development of modules of minimum 10 m²

Polymem is also working on CO2 separation for cabin air recycling.

CO2 CAPTURE TO FIGHT CLIMATE CHANGE

Polymem is involved in the European CO2 capture project MEMBER to develop new composite membrane comprising a porous support covered by a dense permselective skin.

https://vimeo.com/user8315910/download/344387517/553ca6e437

Polymem has designed and built a unique coating machine which permits to fabricate multi layers thin film composite hollow fibers with several layers laid on the membrane surface.

Funded by : H2020-EU.2.1.2. – INDUSTRIAL LEADERSHIP –

Logos :

Filtration of micropollutants and nanoplastics

Separation of micropollutants: Urine micropollutants removed at source using new toilet and new water treatment processes.

A question of public health and preservation of our environment.

In our aquatic environments, there are many micropollutants, which leads to a lot of activity and human consumption, including many drug residues.

Source separation and differential treatment of our urine / greywater and sewage wastewater would reduce the ecotoxicological impact of our releases.