Expertise

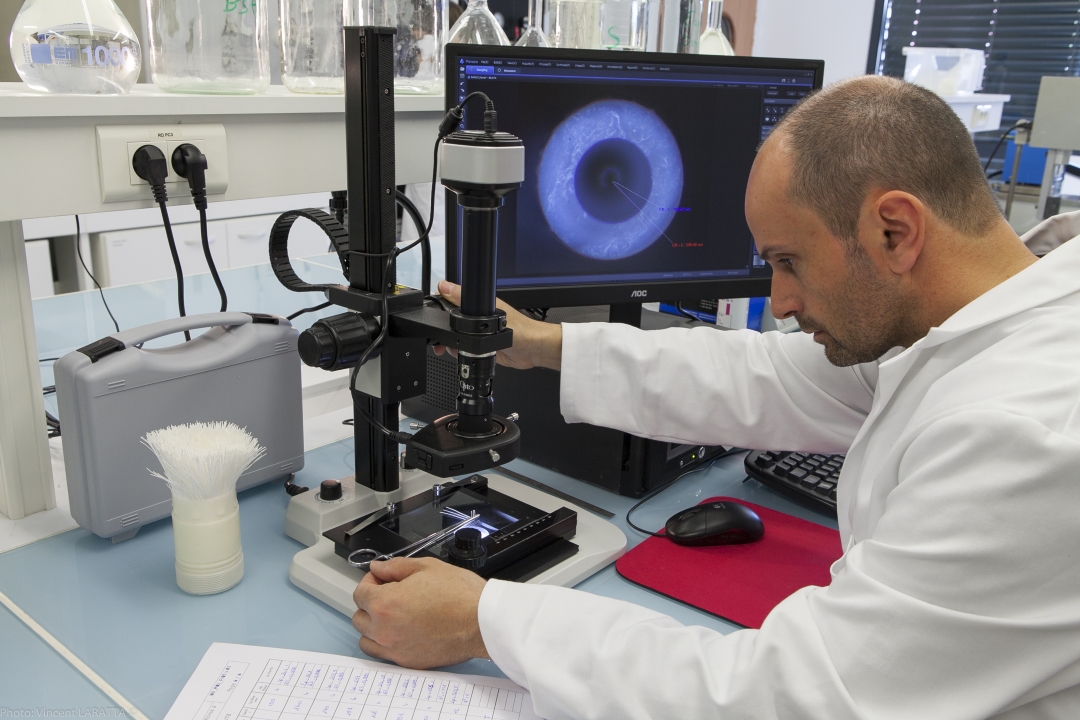

Polymem, whose heart of business is the development and manufacturing of hollow fiber membranes, has the material and human resources as well as skills and specific knowledge for expertise and the replacement of membranes.

Expertise

R & D and Quality Control Teams are able to achieve comprehensive expertise of membrane and membrane modules.

These services aim to analyze the structural state of hollow fibers (any brand) and / or fouling state of hollow fiber membranes, they can also test cleaning solutions, validate the use of cleaning or conditioning products…

These expertise services are made on demand featuring:

-

-

-

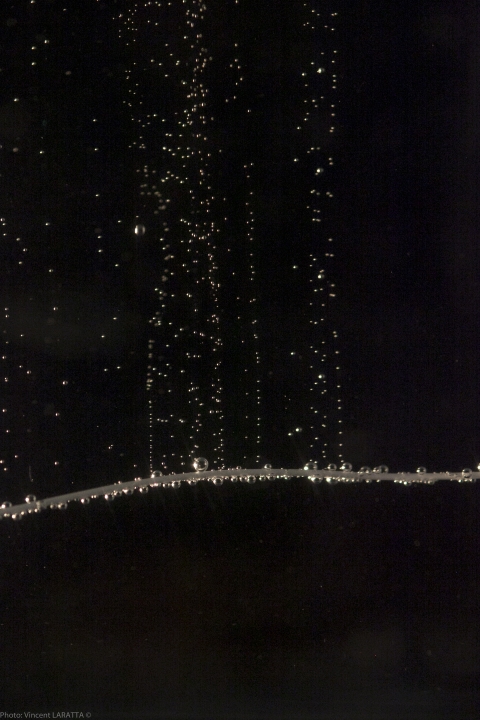

- Integrity test and permeability test of the hollow fiber cartridge or module

- Repair of damaged fibers

- Disassembly of modules or cartridges and product design analysis

- Extraction of the hollow fibers (validated procedures and methods)

- Fibers autopsy: implementation of characterization tests for estimating the remaining life

-

-

Tests carried out by Polymem

-

-

-

- Fiber Dimensions

- Fiber Mechanical Properties

- Fiber Permeability

- Integrity fiber / air permeability

- Fiber compaction pressure

- Fiber Retention Rate

- Fiber bubble point: first bubble point pressure and burst pressure

- Porosity (inner surface, outer surface and / or wall), average porosity

- Distribution of molar masses

- Surface hydrophilic properties

- Chemical and textural surface analysis

- Molecular Weight CutOff (MWCO )

- Adsorption of biomolecules

- Fiber mechanical fatigue test

- Fiber chemical fatigue test

-

-

Polymem is present on the membrane replacment market, on installations fitted with its own membranes but also on installations fitted with competing membranes, with the unique advantage of Polymem of presenting the latest membrane generation, validated and approved for water treatment plants consuming less energy and less chemicals.